The wood encyclopaedia

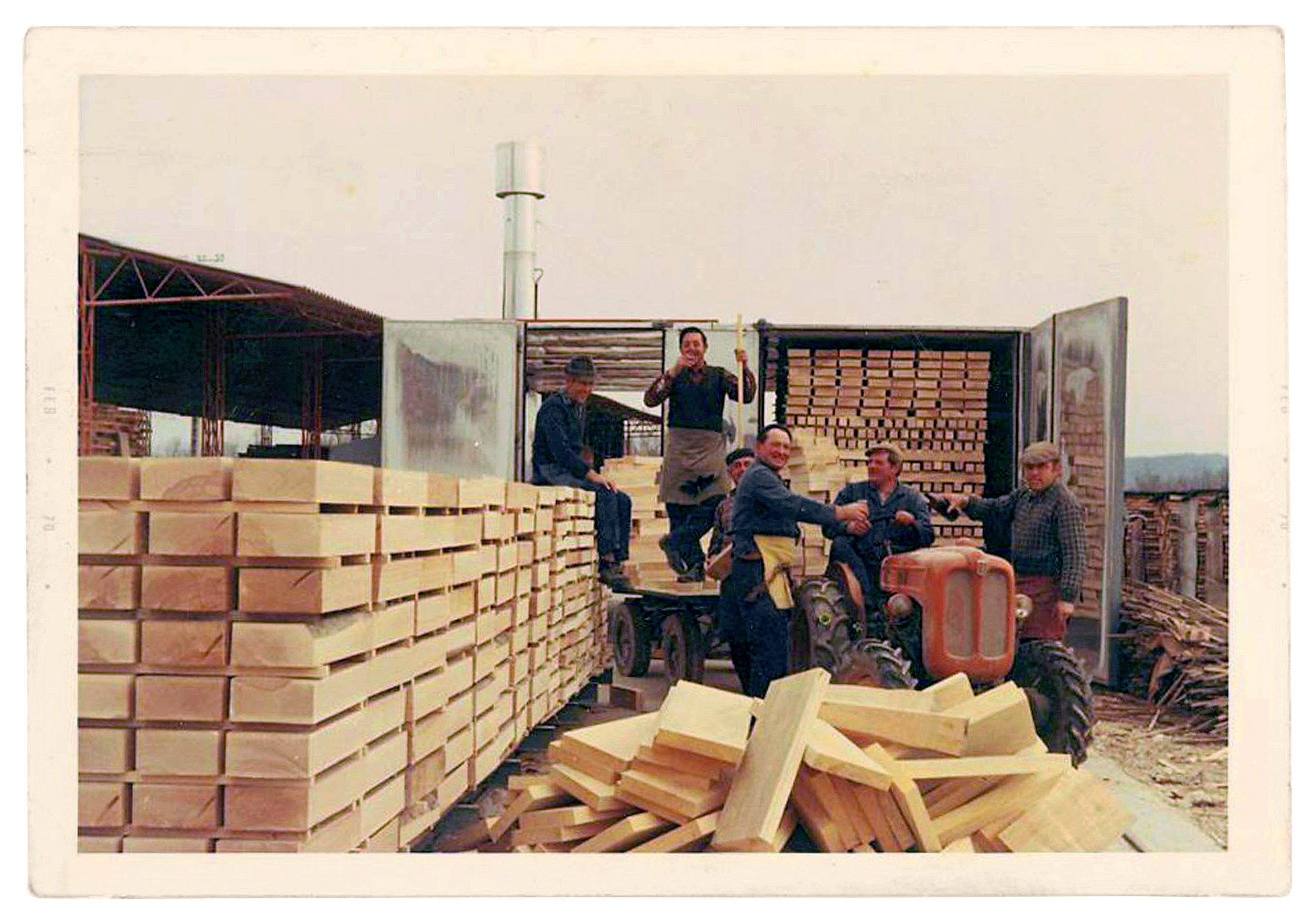

The story of Romanutti Legno goes hand-in-hand with that of its founder, Mario Romanutti, and his wealth of wood-centric knowledge and expertise acquired over ninety years.

Mario was the first businessman in the chair manufacturing district to manage the wood-drying kilns belonging to his family’s firm, where he tested and perfected the prototypes submitted to him.

In 1987 he demonstrated great far-sightedness when he launched his company, which is now among the top vacuum driers in Europe. He always combined his multi-decade practical experience with a particular openness towards the use of cutting-edge technology in order to perfect both the drying operation and his work tools (the kilns).

Now, after his death, his children Francesco and Francesca are running the company and, with the same passion and skill as Mario, they furnish the finest wood-drying service for Italian and international customers.

Wood is a living material

Every drying process must take several variables into consideration: the type of wood, its thickness, the final product required, even where it will be used.

Not forgetting the wood’s and the customer’s timescale needs.

A study of the wood-drying procedure exists, but it is insufficient and there are no process standards or protocols.

By the same token, the kilns can be programmed, but the programme must be adjusted – taking into account all the variables – for each operation.

Only experience and direct contact with the wood gradually allow someone to acquire the knowledge and skill which guarantee an excellent outcome. Constant supervision and human input are the only way of achieving this goal.

Our secret for achieving excellent results:

we love what we do.

Each drying operation is a different story

For anything to do with timber, drying is the first step. It is an increasingly requested procedure, one that has become essential in order to obtain a stable product that will not shrink in thickness nor width and will guarantee that, after being worked, the final material will not be negatively affected by environmental conditions.

In pursuing this goal, our family business takes personal care of each stage in the procedure, from unloading the wood upon arrival to storing it in our warehouse after drying.

We give advice about the right drying procedure for the best results depending on the quality and conditions of the material, the product which our customer intends to make and variables such as moisture, the environment and the product’s intended use, the type and thickness of the wood and even the season and the length of time since the timber left the sawmill.

Our kilns, the very latest and patented by us, are the state-of-the-art to ensure maximum time savings, procedure safety and the best results.

That is why Romanutti Legno is the only firm of its kind in Italy, the only one that can satisfy all needs.

Francesco Romanutti talks about wood drying

In this interview, Francesco Romanutti, owner of Romanutti Legno, recounts the story of the company founded by his father Mario, a pioneer in wood drying.

He explains how the company has evolved traditional techniques by integrating patented vacuum drying technologies, while maintaining a strong focus on quality and personalized service.

A journey through experience, passion, and innovation that has made Romanutti Legno a benchmark in the sector.